WORLDWIDE WCE is presented as a revolutionary solution for designers and manufacturers of multi-board products.

Discreet design and automation

Automation-ready discrete components offer exceptional design flexibility and facilitate the surface mount reflow (SMT) process, while eliminating coplanarity issues. But what exactly is Solderball Pin™ Technology and how can it transform the industry?

Solderball Pin™: Precision Solder Balls

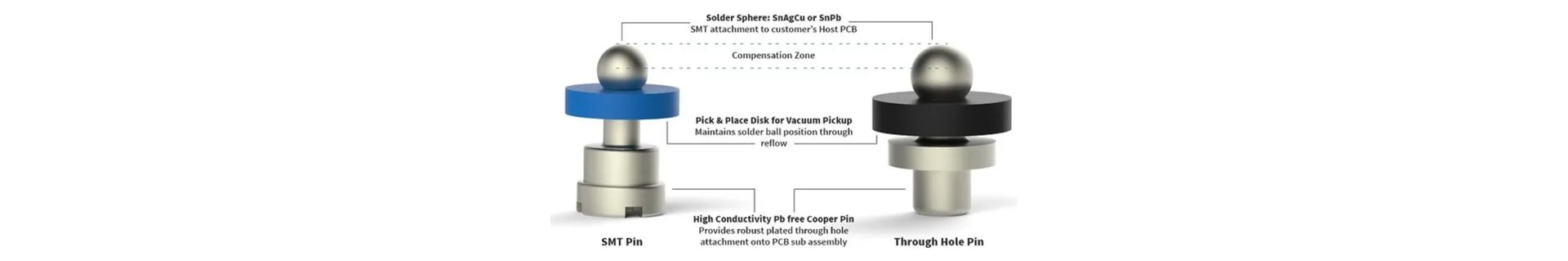

Solderball Pin™ Technology, originally developed by WORLDWIDE WCE, is based on carefully shaped, highly conductive solder balls that are housed in copper terminals. These balls are packaged in continuous ribbons and ready for automation. What makes them so special?

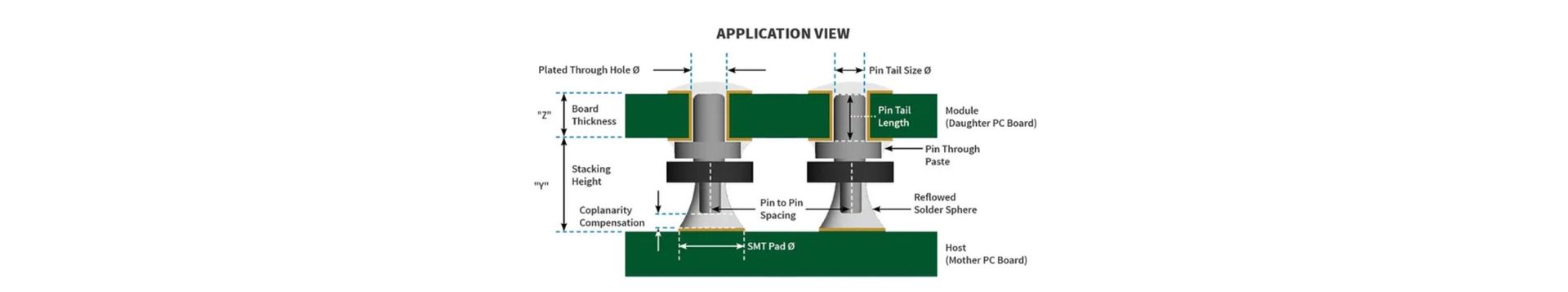

- SMT Compliance: Solderball Pins™ integrate seamlessly into daughter board modules, providing a standards-based SMT interface for parallel daughter board to motherboard assembly. Current standard products include through-hole, SMT, and high-power SMT pin styles, with stack-up heights ranging from 0.100 to 0.170 inches and pin diameters from 0.033 to 0.070 inches.

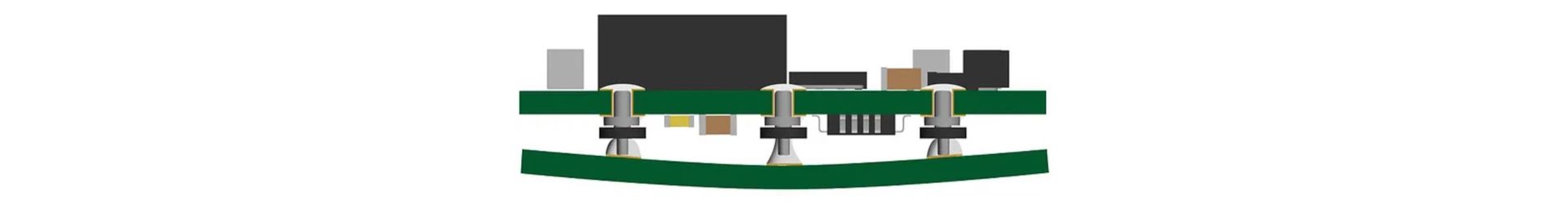

- Automatic Coplanarity Compensation: During final assembly and reflow, Solderball Pins™ automatically accommodate coplanarity differences between PCBs. This ensures that the daughterboard module sits correctly on the motherboard, forming consistent solder joints on all pins. Even on non-coplanar boards, some Solderball Pins™ will compress while others align, ensuring a solid bond.

- Flexible layout and trace optimization: As discrete, self-placeable components, Solderball Pins™ give PCB designers the freedom to determine the optimal pattern and position of individual interconnects based on specific application requirements. They also allow for optimized PCB trace layout and shortened electrical path lengths.

Conserved space, efficient production

Solderball Pin™ Technology plays a crucial role in conserving PCB space, allowing for greater design flexibility and reducing the distance between boards. In a world where products are becoming more compact and densely packed, this innovation is welcome.

Multi-board PCB assemblies, such as small-sized switching power supplies, have become key elements used in electronic products across a variety of industries, including telecommunications, networking, computing, industrial controls, medical devices, and avionics. The need for more compact multi-board solutions is also on the rise, and Solderball Pin™ Technology is paving the way to a more efficient and space-optimized future.

Solderball Pin™ speeds up production