DOME SWITCHES (FROGS):

Free course on: Metal membrane switches "Domes" for membrane keyboards.

Part 1: Types of flat switches for membrane keyboards and their main differences.

There are several types of flat switches for membrane keyboards on the market. The three main ones we are going to discuss today are:

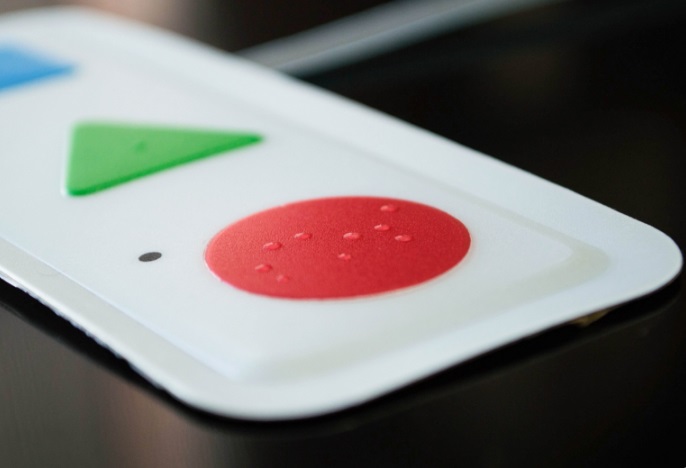

- Dome arrays: These switches are a touch interface between the user and the keyboard. They are made of a pre-cut polyester adhesive and domes.

These domes, which are usually made of stainless steel, are placed under the keys of a keyboard and provide a tactile and audible response when pressed. When a key is pressed, the dome is crushed, closing a circuit and sending a signal to the device. When the key is released, the dome returns to its original shape, opening the circuit.

- Round & Double Radius Domes: These switches are designed for applications where space and height are critical. They are more robust for overloads, over-travel testing, and sweet spot testing.

They are versatile and are commonly used in keyboards and other input devices. They offer good tactile feedback and are durable, making them suitable for applications that require high reliability.

- Switch’Air™ 4 legged domes: These switches use a technology patented by Nicomatic that creates an air cushion between the metal domes, preventing the domes from sticking together.

This design can enhance the tactile feedback of the switches, as the air cushion provides additional resistance when the switch is pressed. This can make the switches more satisfying to use and can improve input accuracy.

Part 2: Characteristics of flat switches for membrane keyboards

The characteristics of these switches can be divided into electrical, mechanical, thermodynamic, and mounting:

- Electrical: The switches have a switching voltage of 0.1 to 100 V and a switching current of 0.005 to 100 ma DC.

They make flat switches for membrane keyboards versatile and suitable for a wide range of applications. However, it is always important to consider the electrical specifications of your device before selecting the appropriate switch.

- Mechanics: The switches are made of stainless steel with a nickel coating.

They make flat switches for membrane keyboards a reliable and efficient option for many devices.

- Thermodynamics: The switches can operate at temperatures from -40°C to +105°C.

This means that they can withstand extreme conditions of cold and heat, making them suitable for use in a variety of environments and applications.

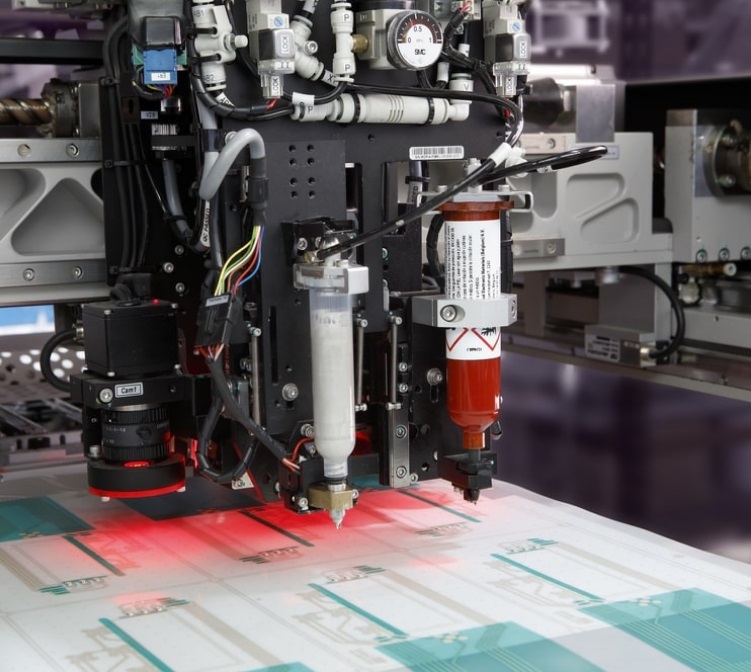

- Assembly: The switches are applied to the PCB after removing the backing and aligning the matrix in a single operation.

Membrane keyboards are easier to build since all the keys share the silicone surface (the membrane).El mecanismo de los interruptores es infinitamente más simple que el que encontramos en los teclados mecánicos.

Part 3: Problems when choosing between different models and characteristics to consider

When choosing between different switch models, several problems may arise. For example, it can be difficult to determine which model best suits our needs. Here are some features we should look for:

- Durability: How long will the switch last under constant use?

- Sensitivity: How much pressure is needed to activate the switch?

- Size: Will the switch fit in the available space in our product?

- Cost: Is the switch within our budget?

Part 4: Examples of final products

Flat switches for membrane keyboards are used in a variety of end products. Some examples include:

- Appliances: Membrane switches are used in microwave keypads and flat remote controls.

- Consumer electronics: Membrane switches are ideal for consumer electronics applications, such as calculators, GPS systems, PC mice, joysticks, cars, etc.