WorldWide WCE, a leader in industrial automation solutions, has launched the KDE100 Series of magnetic rotary encoders. Designed to overcome the limitations of traditional mechanical encoders, the KDE100 offers exceptional accuracy in critical applications.

Contactless Innovation

Unlike conventional mechanical encoders, which use metal contacts prone to wear and contamination, the KDE100 employs the angular rotation of a diametrically opposed magnet to determine its position. This eliminates the need for mechanical components and ensures contact-free operation, even in harsh environments.

Smart switch function

The KDE100 also incorporates a switch function, but instead of the mechanical switch used in most encoders, proximity sensing determines the height of the magnet above the sensor. When the magnetic force is less than a predefined threshold, the user's application can detect that the switch is active. Additionally, various thresholds can be set to measure the pressure exerted on the button.

Flexibility and options

The KDE100 Series is offered in several configurations:

- Voltage: Selectable between +5.0 Vdc or +3.3 Vdc.

- Direction: Four steering directions available.

- Material: Choice of brass or plastic housing.

- Rotation: Continuous or limited to 320°.

- Shaft Type: Available in 6 mm (D-type) or 6 mm (T18 spline).

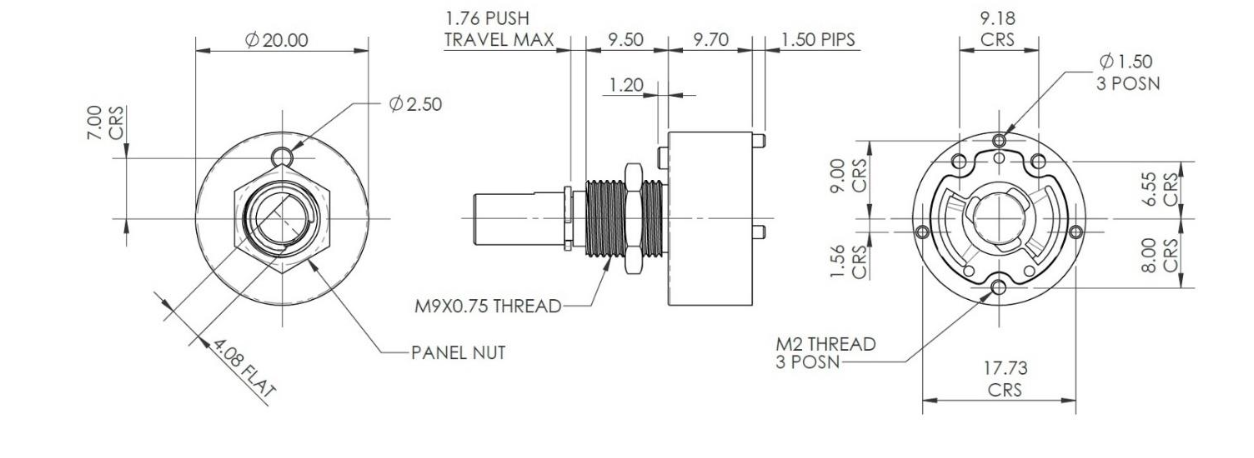

Dimensions

The KDE100 can be supplied as mechanical components (shaft, housing, spring, magnet) for users to add their own electronic circuits, or as complete units with a PCB equipped with a magnetic sensor and a cable to connect to the main hardware.

Precision non-contact encoder KDE100