In the fast-paced world of electronic systems, data multiplication could have disastrous consequences if the impact of crosstalk is not anticipated. Under an electromagnetic disturbance (EMI, RFI or EMP), the cable conductor acts as an antenna and picks up the radiated signals. Receiving this interference undoubtedly affects the integrity of the initial signal.

Today, data rates are increasing exponentially and high-speed protocols are ubiquitous. Proper shielding is a key part of the design. The most efficient shielding method is to enclose the cable in a metal braid, which is then grounded at one or both ends of the cable by the network nodes – the connectors and backshells.

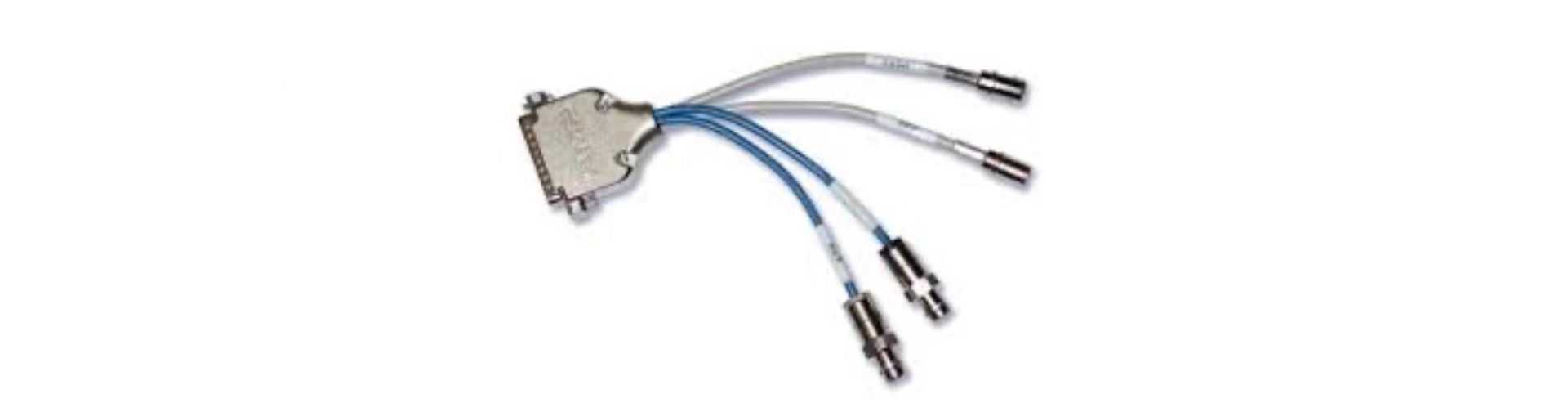

The rear shell, as the back of the MIL-DTL-83513G DMM connector, is used to secure the cable and prevent stress on the soldered or crimped part of the contact. Additionally, it protects against electrical interference (EMI/RFI protection) with a transfer impedance (Zt) less than 200 mOhm from 10 kHz to 400 MHz. Made of 6061 aluminum with a chemical nickel finish, it protects against mechanical damage.

The rear ducts are designed in an ellipse shape, fully compatible with a Band-it type system. Bands and fastening tools are available on our website. The openings allow for fastening cables with a Serflex system and also for grounding the shield of the twisted pair cable. There are 2 designs available of our rear housings: split and mono.

The split rear housing is fully compatible with all DMM connectors and is designed as a two-piece housing. The fixing hardware is mounted on the connector, and the locking of the two parts of the housing does not interfere with the harness, which was manufactured independently at an earlier stage. This results in easy and quick assembly.

The mono rear housing is fully compatible with all DMM connectors. Lighter, smaller and more economical, it is a smart and cost-effective solution for the series production stage. The fixing elements are integrated into the housing, making the assembly process even easier.

EMI filter housing