WorldWide WCE introduces an advanced solution for rapid insertion of pins and terminals, eliminating the need for secondary soldering and improving efficiency and strength in industrial connections.

The implementation of push-pin technology has emerged as a key solution to overcome secondary soldering challenges. WorldWide WCE introduces an innovative solution that enables rapid insertion of compatible pins and terminals, eliminating additional soldering steps and providing high retention strength.

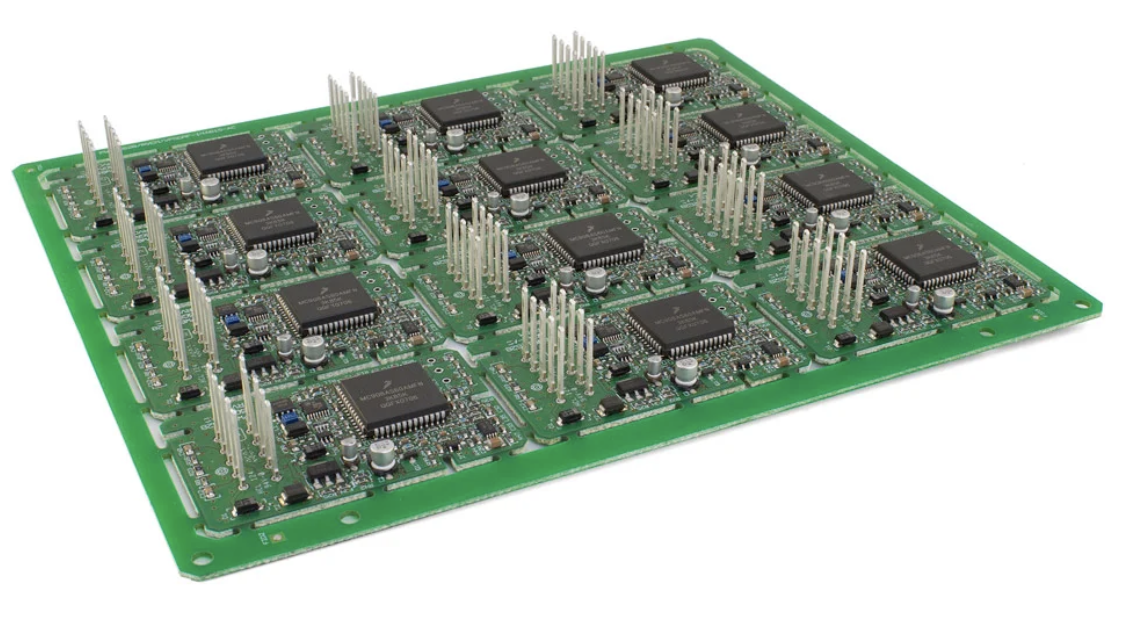

Press-in pin technology, also known as interference fit, has been widely adopted in the automotive and telecommunications industries. This method has eliminated the need for soldering in multi-pin interconnect systems and continues to evolve to meet today's manufacturing demands.

The main challenge is to balance insertion force and retention. An optimal retention force must be close to the insertion force to ensure a robust connection. WorldWide WCE offers solutions that ensure solderless and gas-tight internal connections while maintaining a high normal force in the through-hole (PTH) of the PCB.

PCB assemblies with push-fit terminals allow for pin removal and replacement without damaging the board. This technology is ideal for fine-pitch SMT designs, where soldering issues are critical. Push-fit pins eliminate the need for soldering, reducing costs and improving automation.

WorldWide WCE supplies push-fit pins in continuous reel formats for integration into SMT or through-hole processing lines. These pins can be automatically inserted as discrete interconnects or as pin header connectors.

Automated insertion of press-fit pins is typically performed at the end of the production process, after all SMT components have been placed and soldered. This allows all SMT processes to be performed independently of interconnect assembly, reducing costs and simplifying production.

In summary, WorldWide WCE snap pin technology improves efficiency, reduces costs and optimizes automation processes in industrial manufacturing.

Automation: Pressure Parts