SINGLE PHASE SOLID STATE RELAYS

Free course on: Single-phase solid-state relays.

Part 1: Types of single-phase solid state relays

There are different types of solid state relays. Some of the most common are:

- Zero-switching SSR (ZS)

The Zero-switching SSR, also known as "Zero-crossing switching", is a common type of solid-state relay used in industrial applications.

Operation:

- The ZS is activated when the alternating current (AC) signal crosses zero. This means that the output voltage is activated at the exact moment when the waveform of the alternating signal changes from positive to negative or vice versa.

- By synchronizing the activation with the zero crossing, electrical noise and interference in the system are minimized. This is especially important in sensitive applications or where precise switching is required.

Advantages:

- Noise reduction: By activating at zero crossing, the ZS prevents sudden transients and reduces electromagnetic noise.

- Longer lifespan: Soft switching extends the life of the relay and reduces wear.

- Less interference: By avoiding abrupt switches, interference with other components of the circuit is minimized.

Applications:

- .Control of resistive load (for example, heaters, lamps).

- Control of alternating current motors.

- Heating, ventilation, and air conditioning (HVAC) systems.

- Lighting equipment and appliances.

Considerations:

- The ZS is not suitable for inductive or capacitive loads, as it can cause switching problems.

- The choice of the appropriate SSR must be based on the current, voltage, and specific application.

2. Instant ON SSR / IO (Instant connection)

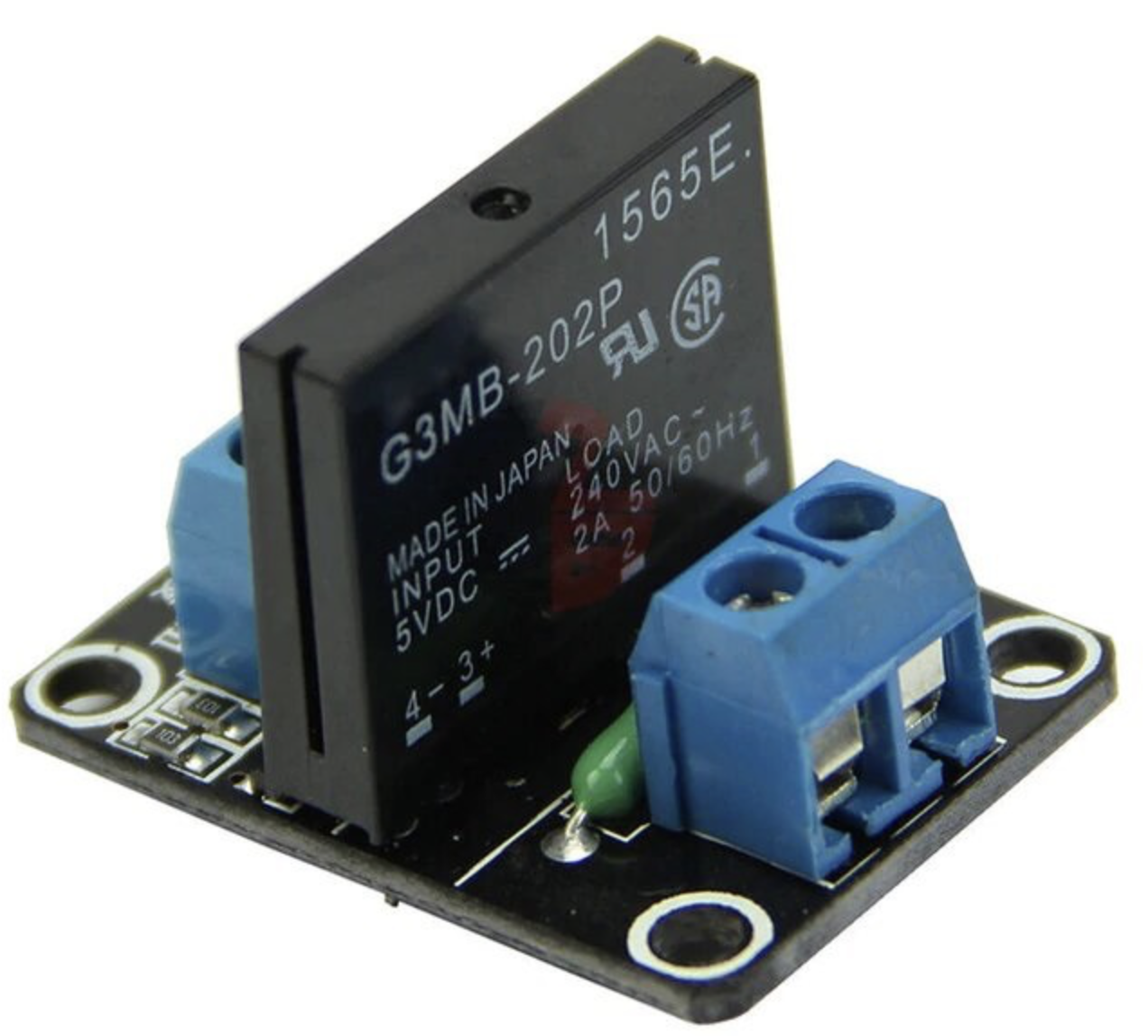

The Solid State Relay (SSR) is an electronic device that operates similarly to the traditional electromechanical relay, but without moving parts. Unlike conventional relays, which use armatures and contacts to switch states, SSRs employ semiconductors to achieve the same function.

Features and advantages of the SSR:

- Low input current: SSRs require an input current in the milliamp range, making them more efficient compared to electromechanical relays.

- Longer lifespan: Due to the absence of moving parts, SSRs have a longer lifespan and less wear.

- Absence of current spikes: The contacts of electromechanical relays can generate current spikes when switching states. In SSRs, this problem does not exist due to their semiconductor-based design.

- Instant activation: This type of SSR applies the voltage to the load at the exact moment the control signal is applied. Furthermore, it remains activated until the next zero crossing after the control signal disappears.Esto permite un control más preciso y rápido en aplicaciones específicas.

In summary, SSRs offer advantages such as greater durability, lower energy consumption, and a faster response compared to traditional electromechanical relays.

3. Peak Switching SSR / PS (connection to peak voltage)

The Peak Switching SSR (Solid State Relay with Voltage Peak Connection) is a device that applies voltage to the load at the first voltage peak that feeds it, after the control signal is applied. Below, I provide you with more details about this type of SSR:

- Operation: When the control signal is activated at the input terminals, the SSR applies voltage to the load at the first peak of the power signal. It then remains activated until the next zero crossing after the control signal disappears.

- Advantages:

- Precision: The Peak Switching SSR allows for more precise control by applying voltage at the optimal moment during the power signal cycle.

- Inrush current reduction: When activated at the first voltage peak, it helps to limit the initial current (inrush current) flowing to the load.

This type of relay is especially useful in applications where a quick and precise response is required. For example, in temperature control systems, lighting, or electric motors.

4. Analog Switching SSR / AS (Analog connection)

The Analog Signal Solid State Relay (SSR) is an electronic device that offers a more precise and proportional switching method compared to solid state relays that operate through digital switching. Below, I provide more details about this type of SSR:

- Operation: The SSR with analog connection has an internal synchronizing circuit that exerts phase or angle control. This allows the output of the SSR to be proportional to the input voltage or current. In other words, the SSR adjusts its conduction state based on the applied analog signal.

- Advantages:

- Proportional accuracy: The SSR with analog connection is ideal for applications where a proportional and precise response is required. For example, in temperature control systems, lighting, or electric motors.

- Soft Starting: This type of SSR is useful for gradually starting loads with low voltages, avoiding initial current spikes (inrush current).

- Initial current limitation: The SSR with analog connection also helps to limit the initial current flowing to the load when turning it on.

In summary, the SSR with analog connection is versatile and adapts well to applications where a proportional and controlled response is needed.

Part 2: Characteristics of single-phase solid-state relays

1. Solid state relays have several electrical, mechanical, and thermodynamic characteristics:

Solid state relays (SSR) are electronic devices that control the flow of electrical current without using moving parts.

SSR characteristics:

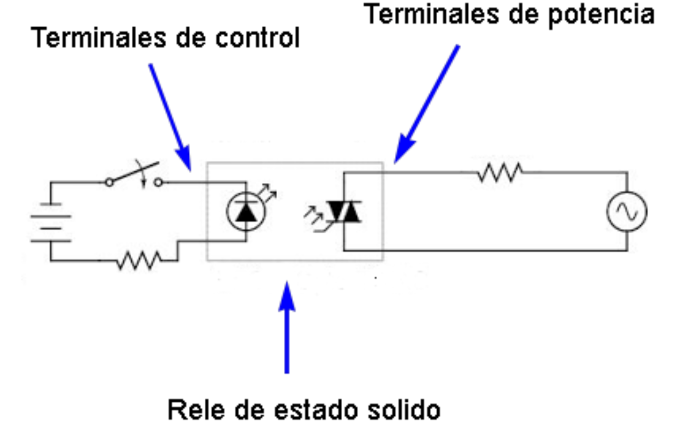

- Independence between circuits: One of the main characteristics of a solid-state relay is that there is no point of connection or interference between the control circuit current and the power circuit current. This is essential to keep the two circuits separate.Por ejemplo, los terminales de control pueden trabajar con una tensión de 24 voltios en corriente continua, mientras que los terminales de potencia pueden manejar una tensión de 230 voltios en corriente alterna.

- Low input current: SSRs require a very low input current, on the order of milliamperes. This is advantageous in terms of energy efficiency.

- Longer lifespan: Since SSRs have no mechanical parts, they do not suffer from internal deterioration, which ensures a longer lifespan compared to electromechanical relays.

- Silent and compact: SSRs do not generate acoustic noise or electrical bouncing, making them ideal for noise-sensitive applications.

- Speed: SSRs are usually faster than mechanical relays due to the absence of moving parts. There is no contact bounce and the release time is considerably shorter.

In summary, solid-state relays offer fast, efficient, and reliable switching, and are particularly useful in applications where a high degree of galvanic isolation and durability is required.

Mechanics: Unlike electromechanical relays, solid-state relays have no moving parts, resulting in less wear and a longer lifespan.

Electromechanical relays:

Solid state relays:

- No moving parts: SSRs have no mechanical components that wear out over time. This means there are no contacts that can wear out or stick, which increases their lifespan.

- Switching speed: SSRs can change state (on/off) much faster than electromechanical relays. This is useful in applications where a quick response is required.

- Silent: Since SSRs have no moving parts, they do not generate mechanical noise during switching. This is especially important in noise-sensitive applications.

- No sparks: Unlike electromechanical relays, SSRs do not generate sparks when switching. This is beneficial in applications where inductive loads are handled or in explosive environments.

- Galvanic isolation: SSRs provide a high level of electrical isolation between the control input and the output load. This helps to prevent damage to other circuit components.

- Durability: Due to their design with no moving parts, SSRs are more resistant to vibrations and adverse environmental conditions.

- Compatibility with microcontrollers and digital logic: SSRs can be controlled directly from low power signals, such as those generated by microcontrollers or digital logic circuits.

- Long lifespan: In general, solid-state relays have a longer lifespan than electromechanical relays.

Thermodynamics: Solid state relays can emit heat due to resistance, which means losses.

Heat dissipation: SSRs, like any electronic component, can generate heat due to electrical resistance inside them. This heat dissipation is an important consideration in the design of applications that use SSRs. Some key points:

- Losses due to resistance: When a solid-state relay (SSR) is activated (conducting current), there is a voltage drop across it due to its internal resistance. This resistance generates heat. The higher the current flowing through the SSR, the greater the heat dissipation.

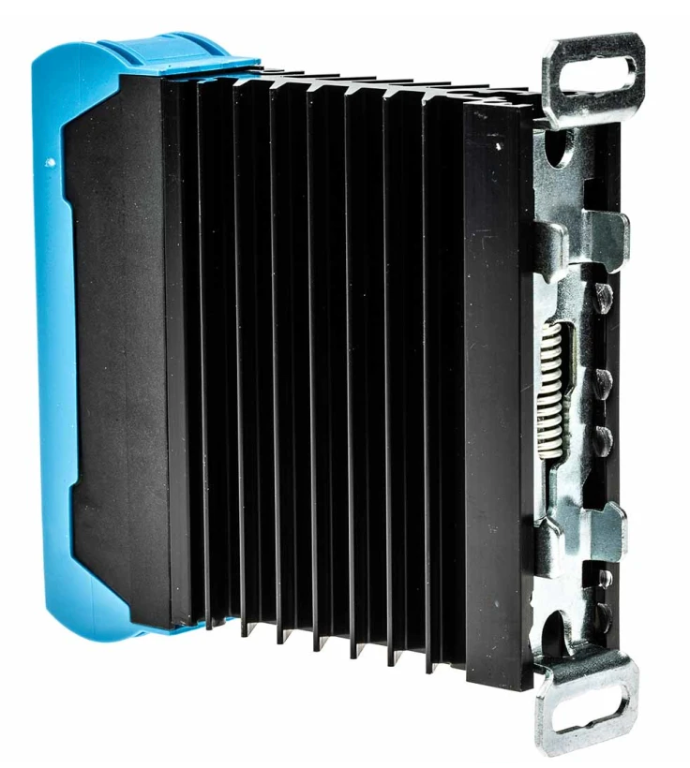

- Heat sink: In high current applications, it is recommended to use heat sinks to keep the temperature of the SSR within safe limits. Heat sinks help transfer the heat generated to the environment.

- Ambient temperature: Ambient temperature also affects heat dissipation. In hot environments, it is important to consider the cooling capacity of the SSR.

Thermodynamic advantages:

- Without moving parts: Unlike electromechanical relays, SSRs do not generate heat due to mechanical movement. This reduces wear and the heat generated associated with moving contacts.

- Quick response: SSRs can switch states rapidly, which minimizes the time during which heat is generated.

- Galvanic isolation: The electrical isolation between the control input and the output load also helps prevent unwanted heat transfer.

In summary, although SSRs can generate heat due to resistance, their advantages in terms of durability, switching speed, and electrical insulation remain beneficial in many applications.

From assembly: Solid-state relays are more compact and allow for more automatable elements.

Compact size: SSRs are compact electronic devices that take up less space compared to electromechanical relays. This is especially useful in applications where space is limited or a more efficient design is needed.

Automation: SSRs are highly automatable due to their electronic nature. Some advantages related to automation are:

- Precise control: SSRs can be precisely activated and deactivated by control signals, such as those generated by microcontrollers or PLCs (programmable logic controllers).

- Integration with digital logic: SSRs can be directly connected to digital circuits, making it easier to automate and program on/off sequences.

- Compatibility with control systems: SSRs are commonly used in industrial automation systems, such as temperature controllers, lighting systems, welding machines, etc.

Additional advantages:

- Reliability: Since they have no moving parts, SSRs are more reliable in environments where vibrations or shocks could affect electromechanical relays.

- Long lifespan: The absence of mechanical wear contributes to a prolonged lifespan.

- Silence: The SSRs do not generate mechanical noise during switching, which is beneficial in sound-sensitive applications.

Part 3: Problems and considerations when choosing a solid-state relay

When choosing a solid-state relay, it is important to consider several factors:

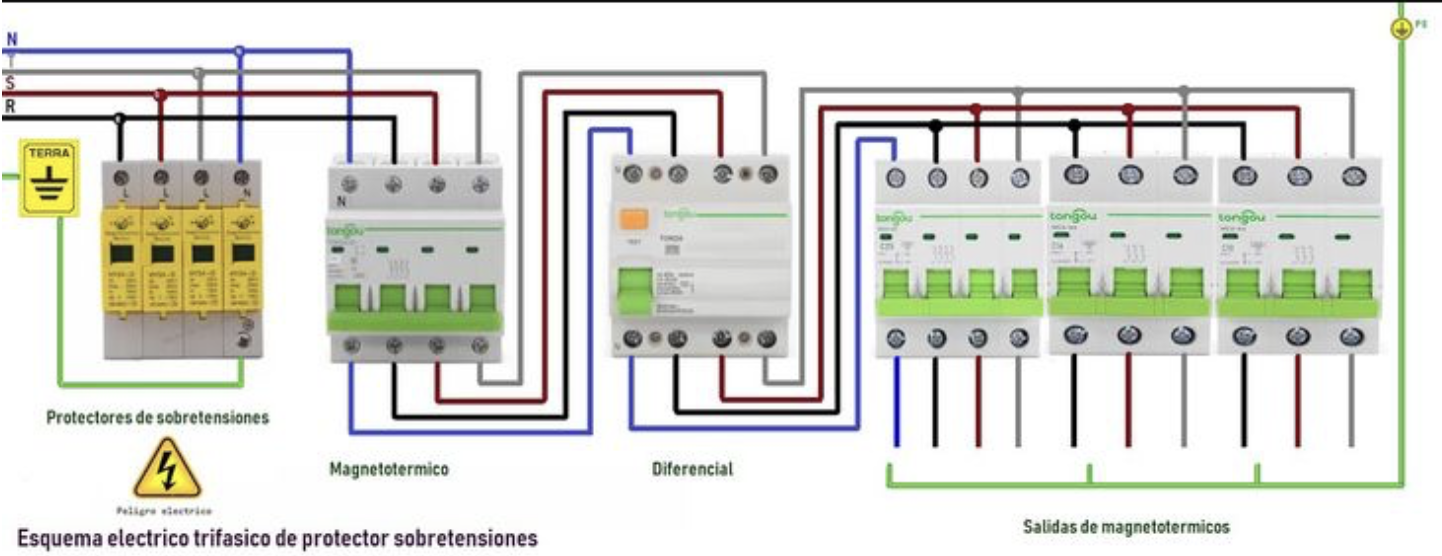

1. Overcurrent and overvoltage:

When selecting a solid-state relay, it is essential to consider the following aspects related to overcurrent and overvoltage:

Undercurrent:

- An overcurrent relay (or overcurrent monitoring relay) is used to protect electrical circuits and devices against the harmful effects of excessive currents.

- It detects when the current exceeds a predefined threshold and automatically disconnects the circuit or sends a signal to take protective measures.

- Prevents cables from overheating, melting, or damaging sensitive electronic components.

- Common applications include transmission and distribution networks

Overvoltage:

- Surges can be external (such as lightning on power lines) or generated internally (by motor starters or welding equipment).

- Solid state relays (SSR) can also be affected by surges.

- Es importante considerar la tensión de entrada y salida al seleccionar un SSR.

Tolerancia a sobrecargas momentáneas: Los relés de estado sólido tienen una baja tolerancia para soportar sobrecargas momentáneas, comparado con los relés electromecánicos.

Advantages of solid-state relays (SSR):

- Connection without zero-crossing function: SSRs can be connected without the need to detect the zero-crossing of the load voltage. This allows for greater flexibility in the application.

- Disconnection at I=0: SSRs can disconnect when the current is equal to zero, preventing electrical arcs and bounces.

- Shock and vibration resistance: Since SSRs have no moving parts, they are more robust in environments with vibrations or impacts.

- Optimal lifespan: The absence of mechanical wear prolongs the lifespan of the SSR.

- High switching frequency: SSRs can change state quickly, even in the order of milliseconds.

- Silent operation: They do not generate noise or sparks when switching.

- Control of low voltage: They are compatible with TTL/CMOS signals.

Disadvantages of solid-state relays:

- Sensitivity to disturbances: The input circuit of the SSR is sensitive to electrical interference.

- Need for external protective elements: They may require heat sinks and protective nets.

- Sensitivity to temperature and overvoltages: SSRs are more susceptible to these factors.

- Technological and conceptual complexity: They require a more abstract understanding than electromechanical relays.

Resistance to current flow: In their active state, solid-state relays exhibit greater resistance to current flow.

- Active state resistance: SSRs have a greater resistance to the flow of current when activated. Unlike electromechanical relays, they have no moving parts. This means there are no mechanical contacts that wear out, but it also implies that their resistance is higher in comparison.

- Tolerance to momentary overloads: SSRs are less tolerant to momentary overloads than electromechanical relays. Therefore, when applying SSRs, we must consider this limitation.

- Coupling: The control signal couples to the control circuit through galvanic isolation. Most SSRs use optical coupling, where an internal LED is activated by the control signal, allowing the control circuit to be electrically isolated from the load.

In summary, SSRs are excellent for switching high-speed currents without moving parts, but we must take into account their resistance and overload tolerance.

Part 4: Examples of use of single-phase solid state relays

Solid-state relays are used in a variety of applications:

Motor control: They can be used to control AC and DC motors, from small motors in appliances to large industrial motors.

- Operation: An SSR consists of a sensor that responds to a control signal (input), a solid-state electronic switch that switches the load circuit, and a coupling mechanism.A diferencia de los relés electromecánicos, los SSR no tienen partes móviles y utilizan semiconductores de potencia como tiristores y transistores para conmutar corrientes de hasta más de 100 amperios.

- Advantages:

- Fast switching: SSRs can switch states in milliseconds, much faster than electromechanical relays.

- Longer lifespan: Lacking mechanical parts, they do not suffer from internal wear.

- Galvanic isolation: The control circuit is electrically isolated from the load, preventing interference.

- Ideal for inductive loads: They can handle inductive loads such as motors without any issues.

- Arranque suave y limitación de corriente inicial: Útiles para evitar picos de corriente al encender cargas.

Regarding motor control, SSRs are excellent for applications that require fast and reliable switching. They can be used for both alternating current and direct current motors. Moreover, their design without moving parts makes them ideal for industrial environments and household appliances.

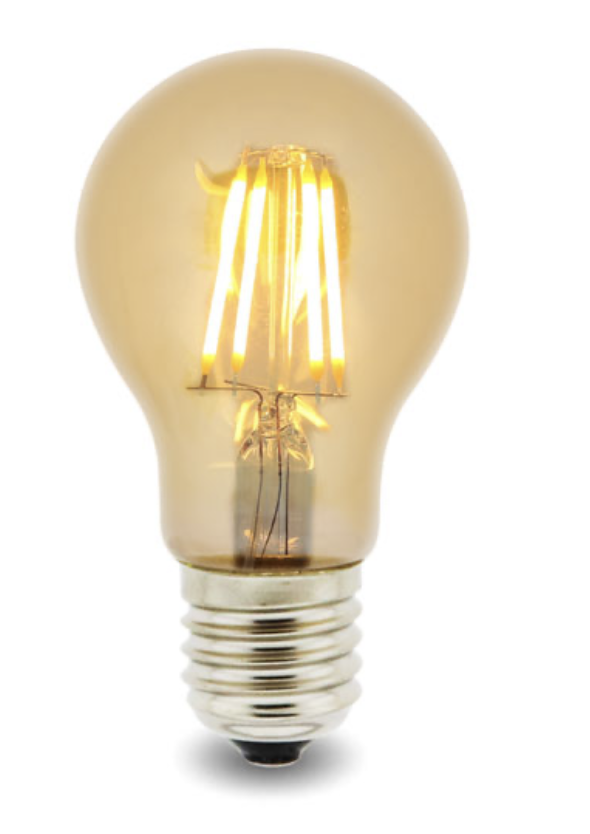

Lighting control: Solid state relays are used to switch loads such as bulbs and LED arrays.

- Lighting control: Solid-state relays are also used to switch loads such as light bulbs and LED arrays. They offer a fast switching speed, which is important for certain lighting effects. Additionally, there is no risk of arc formation or sparks, which could be dangerous in lighting applications. They also prevent contact bounce, which could cause flickering lights..

In summary, SSRs allow small input signals to control much larger loads, and their design without moving parts makes them ideal for applications where durability and speed are important.

Control of heaters: Solid state relays are used to control electric heaters.

Control of heaters:

- Solid-state relays are widely used to control electric heaters. Some key benefits include:

- Durability: Without moving parts, SSRs do not suffer mechanical wear.

- Speed: SSRs can switch quickly, which is crucial for maintaining a constant temperature in heating systems.

- Safety: There is no risk of arc or spark formation, which could be dangerous in heating applications.

- In addition, the SSRs can be designed to change the load when the AC power source is at its peak, preventing damage to the heater from inrush current.

Medical devices:

- In critical medical devices, SSRs are used to control power. Some advantages are:

- Reliable switching: SSRs provide fast and efficient switching.

- No moving parts: This ensures a longer lifespan and prevents internal wear.

- Wide voltage range: They can handle voltage differences from 4 to 32 VDC and currents from 90 to 480 VAC.

- Safety: The lack of mobile contacts eliminates the risk of arcs or sparks, which is crucial in medical environments.